NICKEL & NICKEL ALLOYS

TIG/MIG 501

Pure nickel filler rod / wire for TIG / MIG welding

TECHNICAL DATA

UTS : 42-54 Kgf/mm2

Impact value: 130J

TYPICAL APPLICATIONS

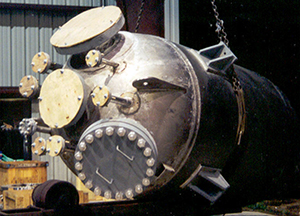

Used for joining and cladding pure nickel grades, e.g. Wnr. 2.4050-Ni 99.8, 2.4060-Ni 99.6, 2.4062-Ni 99.4 Fe, 2.4066-Ni 99.2, 2.4068-LC-Ni 99, 2.4106-Ni Mn 1, 2.4108 Ni Mn 1 C, 2.411-Ni Mn 2. Welding nickel-clad steel plates, nickel to steel and copper to steel. Used as buffer layers when welding or surfacing steels using Cu-Ni and Ni-Cu filler material, tanks, valve bodies, pipe lines, heat exchanger tubes, end plates, etc.

TIG / MIG 511

Monel filler rod / wire for TIG / MIG welding

TECHNICAL DATA

UTS: 48-52 Kgf/mm2

Charpy V notch impact energy: 110J

Shielding gas: Welding grade argon

TYPICAL APPLICATIONS

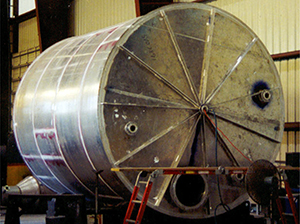

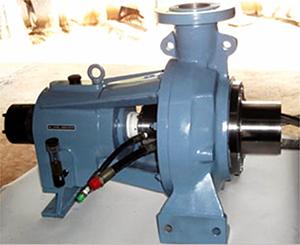

Used for joining and cladding Monel, Monel-clad steels, nickel-copper alloys and alloy steels. Chemical industry, shipbuilding, oil industry, pump impellers, tubes (e.g. heat exchanger of condenser tubes), distillation towers, tanks. Suitable for working temperatures ranging from –196 to + 400ºC.

TIG / MIG 512

Cupro-nickel filler rod / wire for TIG / MIG welding

TECHNICAL DATA

UTS: 35-48 Kgf/mm2

Shielding gas: Welding grade argon

TYPICAL APPLICATIONS

Used for joining and cladding copper-nickel alloys with up to 30% nickel. For Wnr : 2.0806, 2.0812, 2.0818, 2.0822, 2.0830, 2.0836, 2.0842, 2.0862, 2.0872, 2.0878, 2.0882, 2.0890. Also used in shipbuilding, fertilizer and chemical industry, paper and pulp on applications like vessels, condenser tubes, condensers, heat-exchangers, pipelines, valve bodies, etc.

TIG/MIG 517

Nickel based super alloy filler rod / wire for TIG / MIG welding

TECHNICAL DATA

UTS : 62-68 Kgf/mm2

Elongation : 20-30%

TYPICAL APPLICATIONS

TIG/MIG 517 is used for welding inconel 617, incoloy 800, 800 H, 800 HT, 803, HP 45, other heat-resisting alloys with dissimilar metals for high-temperature service up to 1250º C. Also used on valves, pumps, pipelines, heat exchanger tubes subjected to severe chemical corrosion and temperature environment.

TIG / MIG 521

Inconel filler rod / wire wire for TIG / MIG welding

TECHNICAL DATA

UTS: 55-59 Kgf/mm2

Impact energy: > 100J

TYPICAL APPLICATIONS

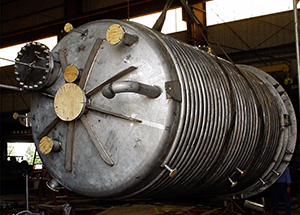

Used for joining and cladding pressure vessels, boilers, fittings, induction coils, furnace parts immersion tubes etc. Welded joints between dissimilar alloys and cryogenic nickel steels. Suitable for all types of steels, Wnr. 2.4605, 2.4630, 2.4631, 2.4669, 1.4876, 2.4816, 2.4856, 2.4858, 2.4867, 2.4869, 2.4870, 2.4951, LC-Ni Cr 15 Fe, Ni Cr 15 Fe Mo. Particularly suitable for welding “black-white” joints sensitive to thermal loading above 300ºC, in order to prevent carbon diffusion.

TIG 521 M

Inconel filler metal for GTAW

TECHNICAL DATA

UTS: 114-116 Kgf/mm2

TYPICAL APPLICATIONS

Used for joining and cladding Inconel, Incoloy, other heat resistant metals. Applications in chemical, steel, fertilizer, refineries, paper industry like tanks, reformer tubes, heaters, heat exchanger, coils etc.

TIG/MIG 524

Inconel filler rod / wire for TIG / MIG welding

TECHNICAL DATA

UTS : 76-80 Kgf/mm2

Elongation : 30-35%

TYPICAL APPLICATIONS

TIG/MIG 524 is used for joining and cladding dissimilar steels, nickel steels and various corrosion-resistant alloys such as alloy 20. The weld metal has high strength over a broad temperature range and has exceptional corrosion resistance, including resistance to localized attack such as pitting and crevice corrosion.

TIG 717

Ni-Cr-Mo filler rod / wire for TIG / MIG welding

TECHNICAL DATA

UTS : 69-76 Kgf/mm2

Elongation : 25-35%

Hardness as-welded : 20-25 RC

work hardened : 30-36 RC

TYPICAL APPLICATIONS

Used for building-up worn out or new tools for hot working, die-plates, forge dies, hot shear blades, hot stripping rolls, mandrel punches, forming tools in foundry and forge, steel rolling and metal working industry.

TIG/MIG 722

Most versatile nickel- chromium- molybdenum tungsten alloy for TIG /MIG welding

TECHNICAL DATA

UTS : 69-77 Kgf/mm2

TYPICAL APPLICATIONS

Used for acetic acid/acetic unhydride, acid etching, cello phene manufacturing, chlorination systems, complex acid mixtures, electro-galvanising rolls, expansion bellows, flue gas scrubber systems, geothermal wells, HF furnace scrubbers, incineration scrubber systems, nuclear fuel reprocessing, pesticide production, phosphoric acid production, pickling systems, plate heat exchanger, selective bleaching systems, SO2 cooling towers, sulfonation systems, tubular heat exchanger, weld overlay-valves, etc.